My Role: Chassis Team Lead

Joined the Planetary Surface Technology Development Lab (PSTDL) after Level 1 design, leading the 3-person subteam through fabrication, testing, and complete redesign of a 375 kg lunar excavation rover's chassis. Responsible for integration of all structural systems into rover as well as a novel drivetrain design.

Design Philosophy: Speed Through Simplicity

Developed a manufacturing hierarchy to maximize build speed with limited resources:

- 3D printed if possible (brackets, spacers)

- Bent sheet metal + rivets (no welding required)

- Bent sheet metal + welded joints

- Square tubing + welding

- In-house machining utilized only when unavoidable

This approach let us build fast and iterate faster; critical when discoveries during integration demanded immediate redesigns. Even the most expensive option, making billet parts, was done in house by team members to save cost.

Level 2: Bringing PRIMROSE to Life

Inherited a conceptual design that needed manufacturability fixes. Key contributions:

- Resolved geometric interferences in CAD before cutting metal

- Designed serviceable subassemblies (learned from automotive work)

- Modified existing suspension hardware for 15-day endurance test

- Result: 30,063 m traversed, 2,987.2 kg excavated and dumped

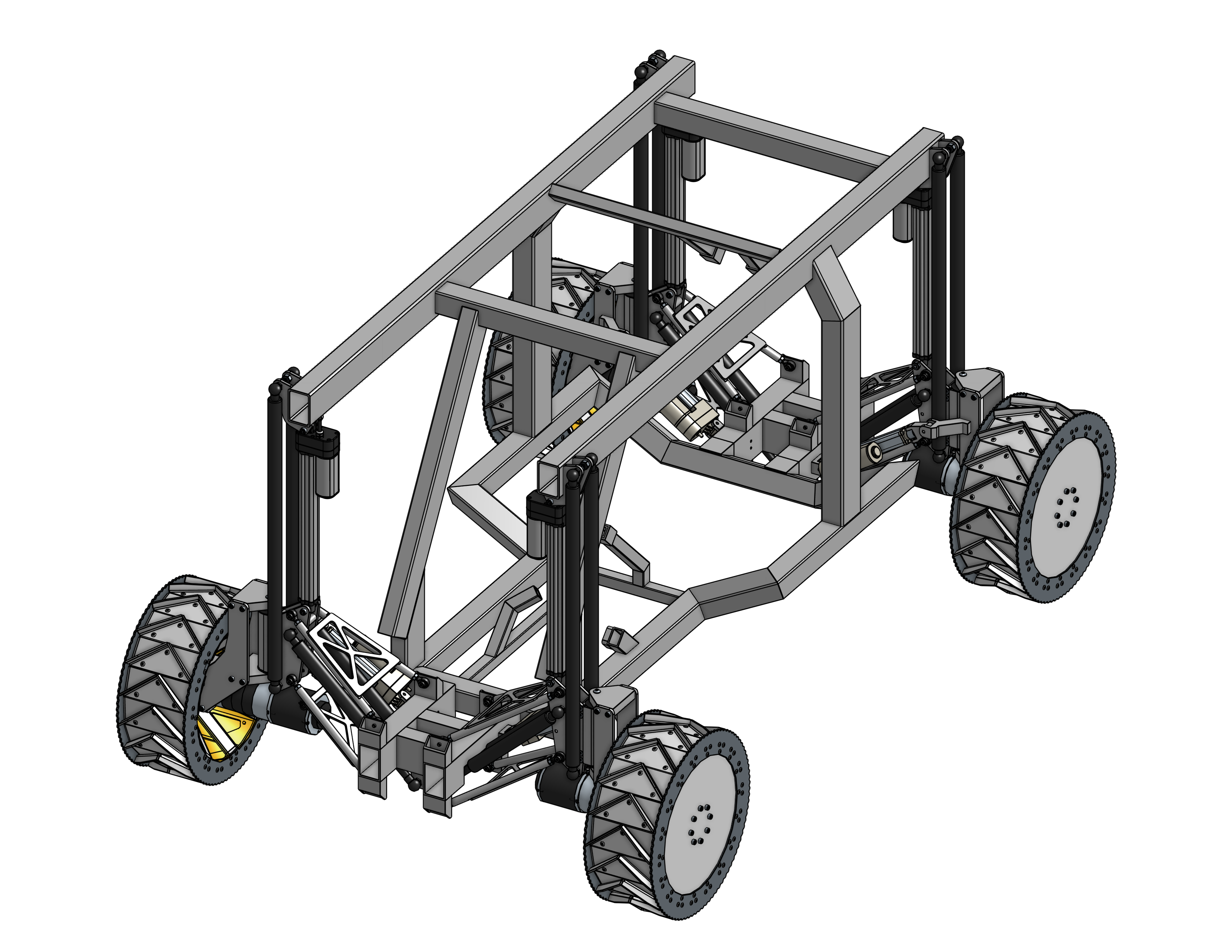

Level 2 rover during endurance test showing original configuration

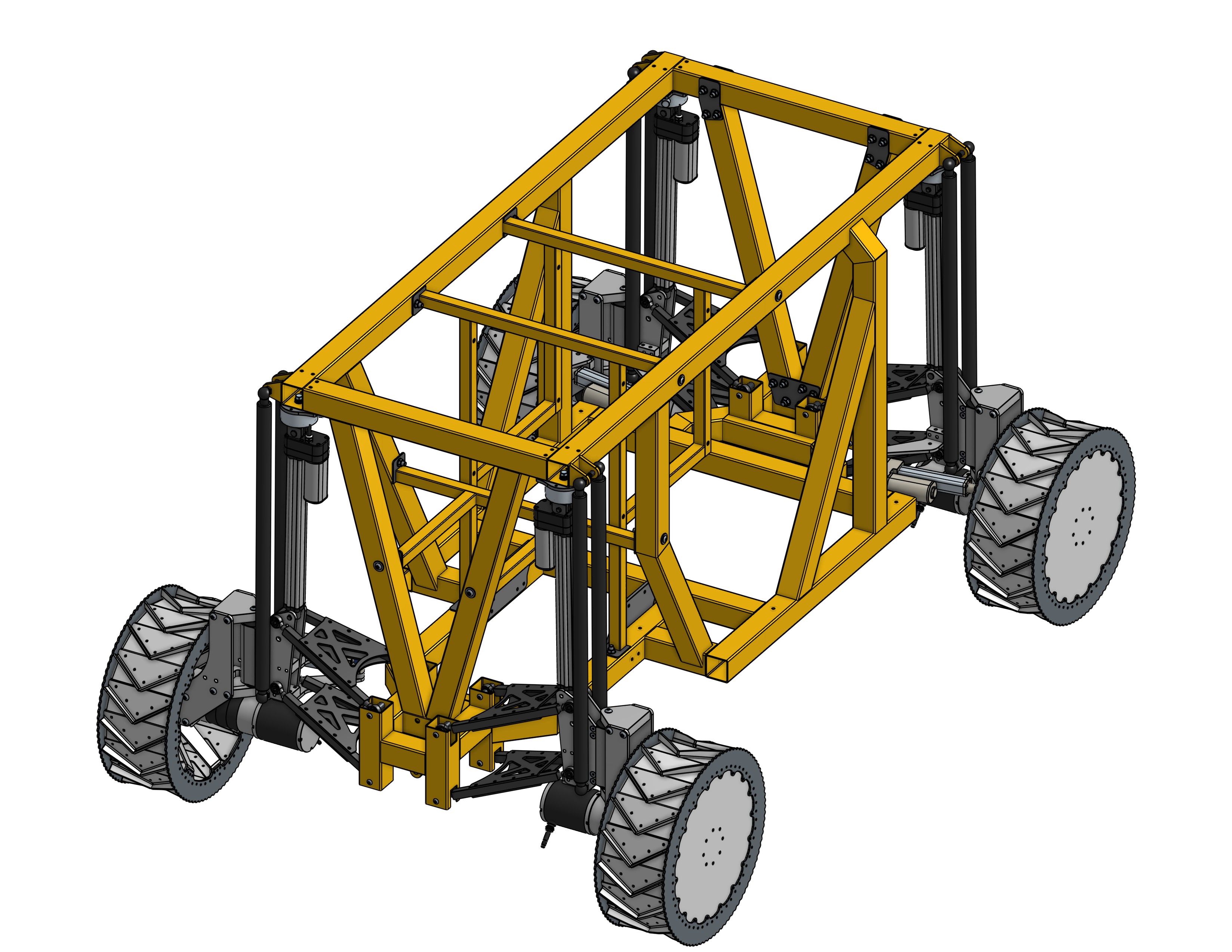

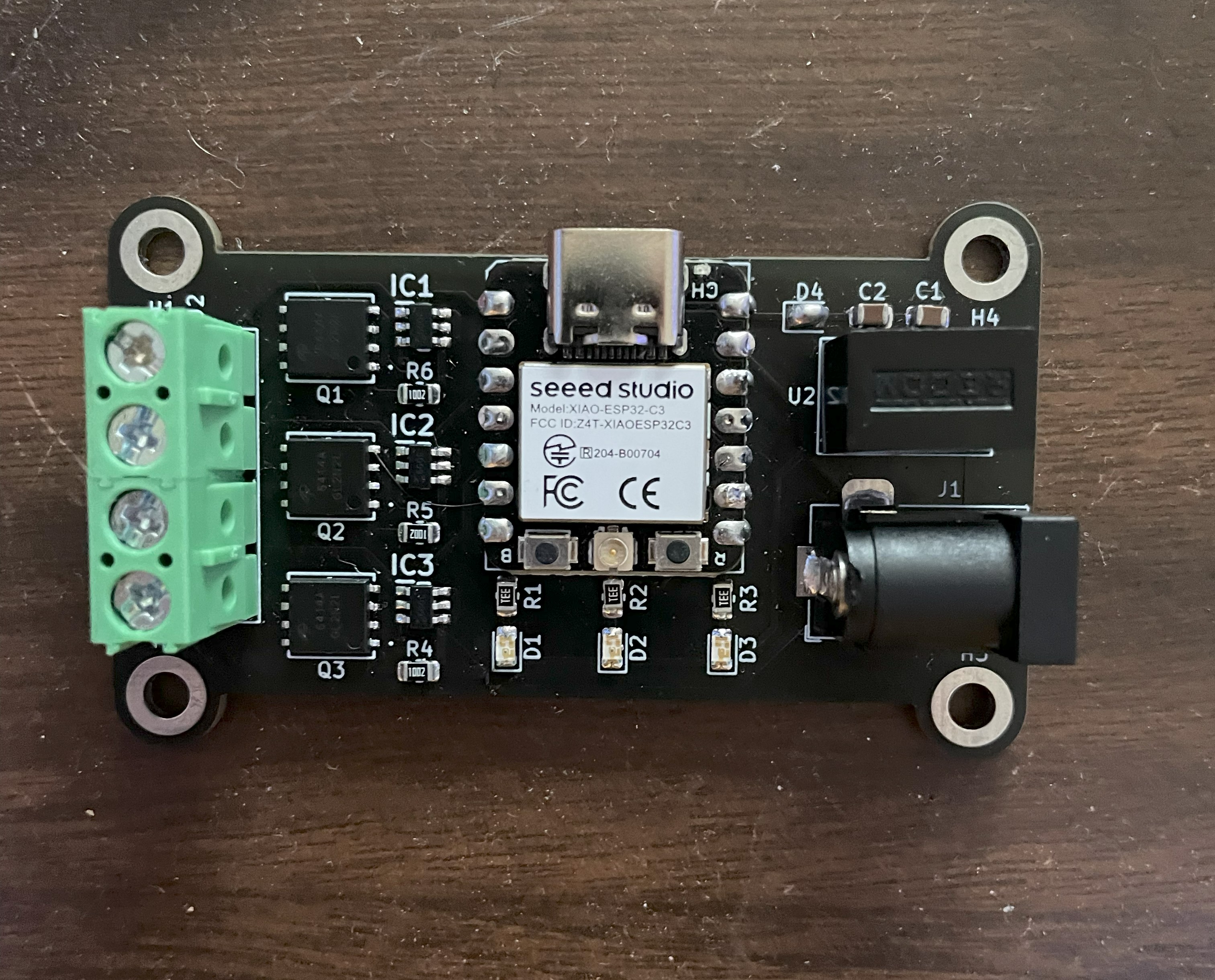

Level 3: Huntsville or Bust

The rover was constantly down for maintenance, necessitating a rework. Worked with chief engineer and team to set new requirements, mainly: wider wheelbase for stability, larger wheels to prevent sinking in sand or regolith, 30°/30° steering capability for better maneuverability. Key contributions:

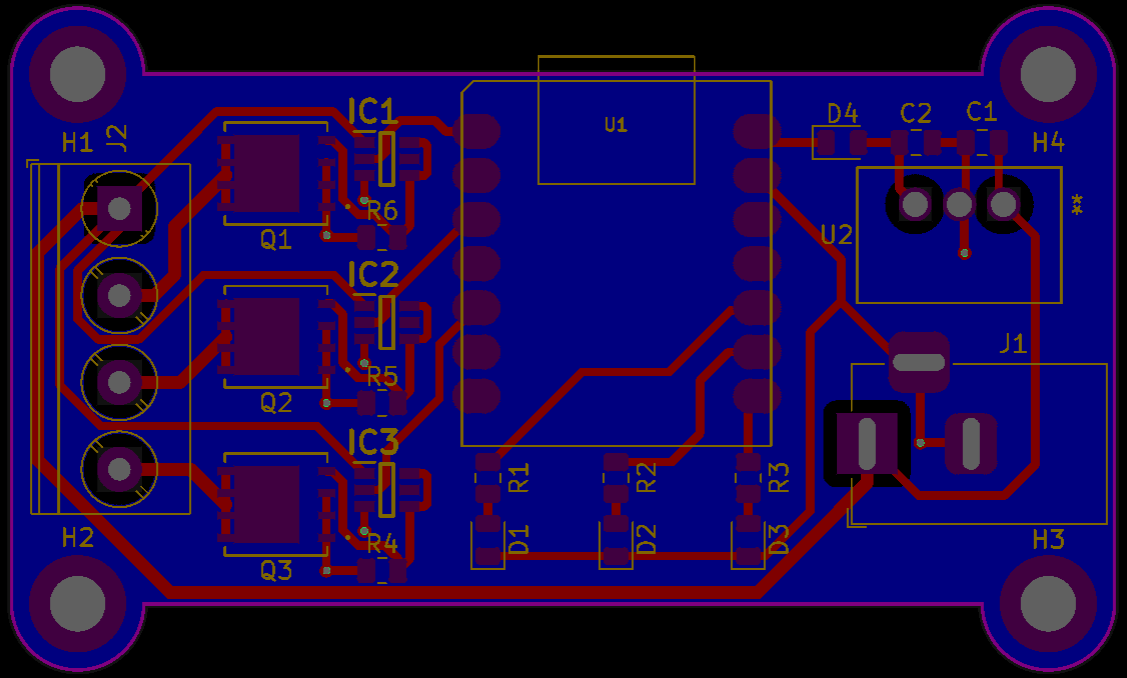

Structural Redesign:

- Converted internal frame from steel to aluminum (weight savings + new electrical system)

- Added frame brackets to accommodate larger wheels and wider wheelbase

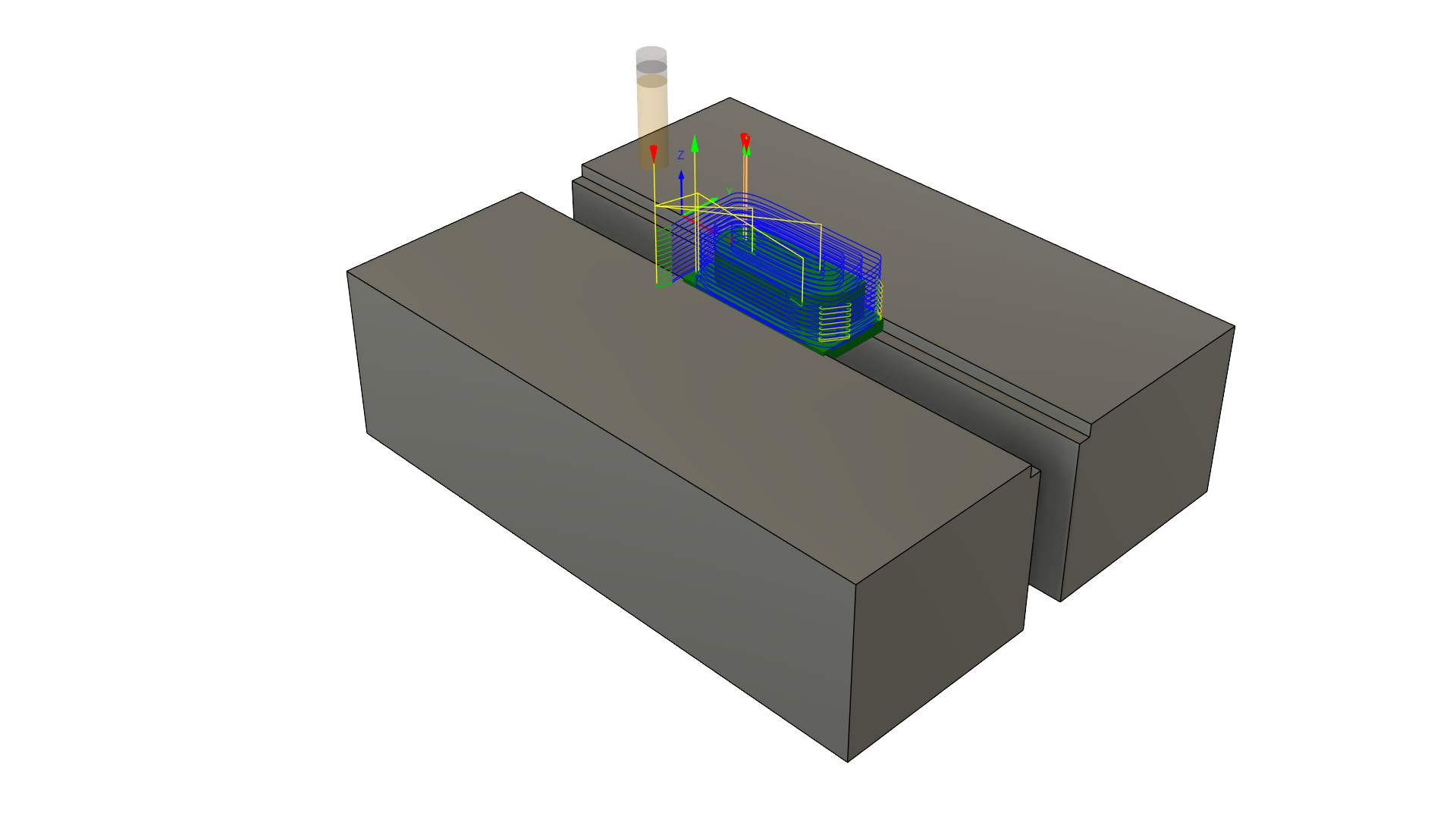

- ANSYS FEA with aggressive FoS (verified against hand calcs)

- Maintained top-down CAD architecture in Onshape, enabling fast design changes

ANSYS quasi-static analysis with frame constrained by free sliding wheels

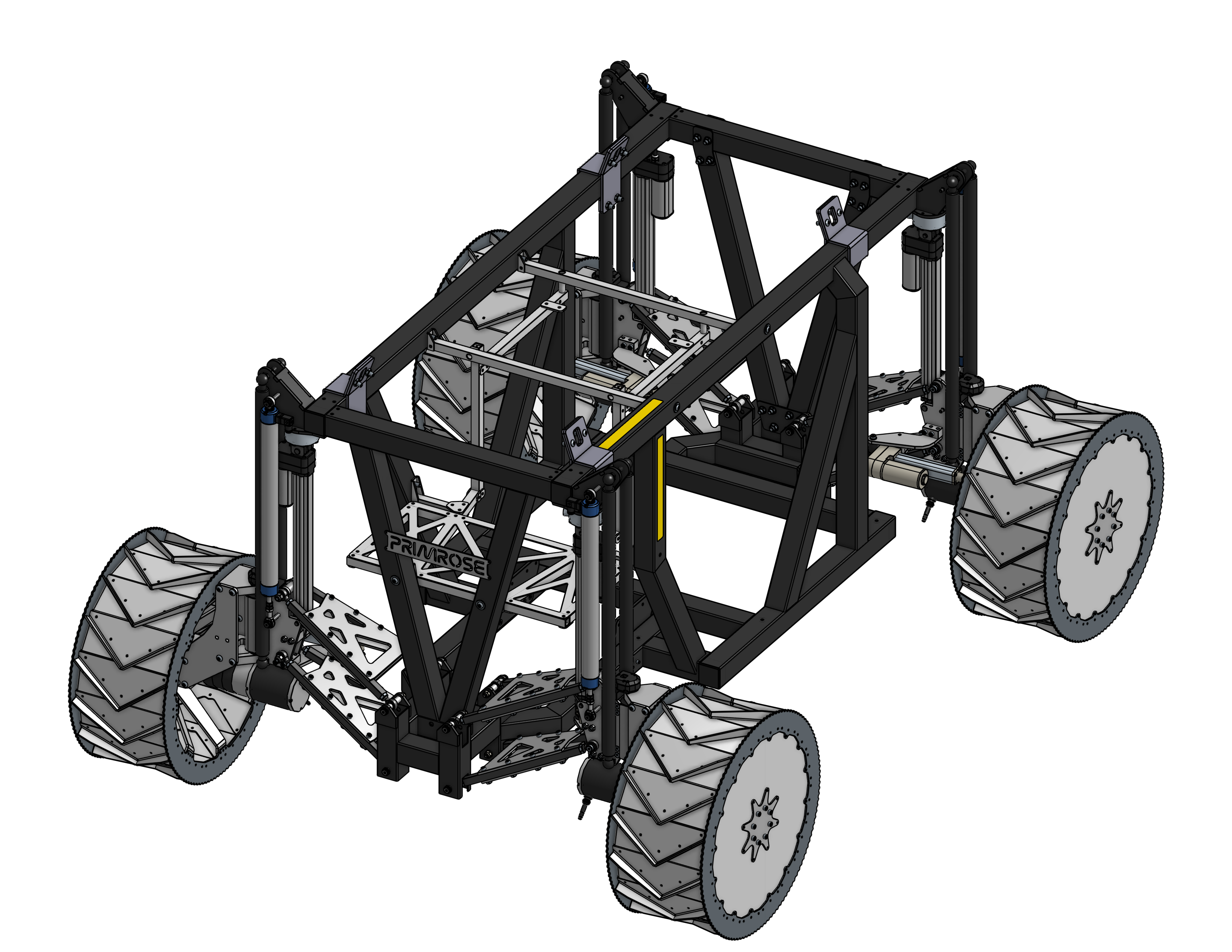

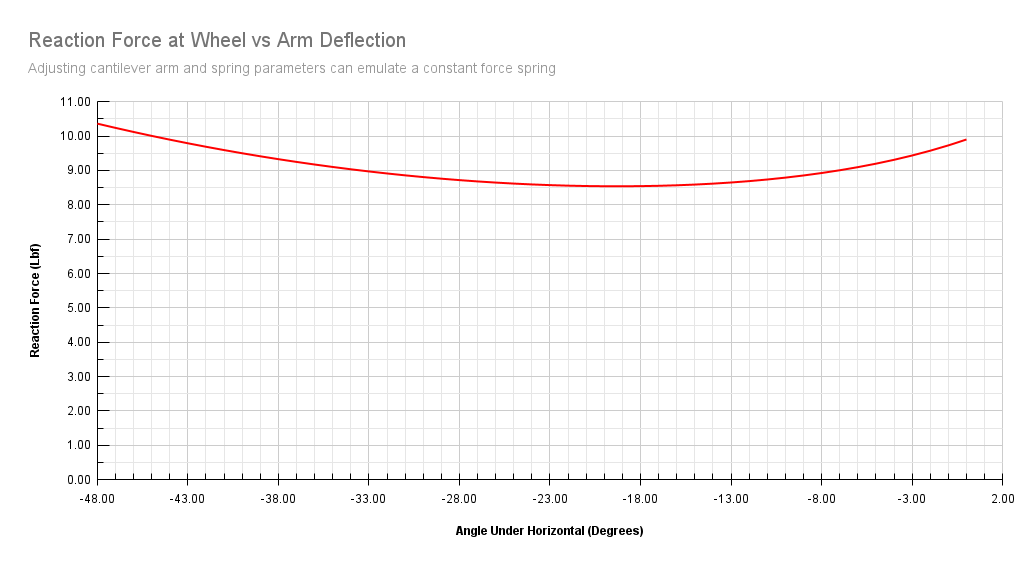

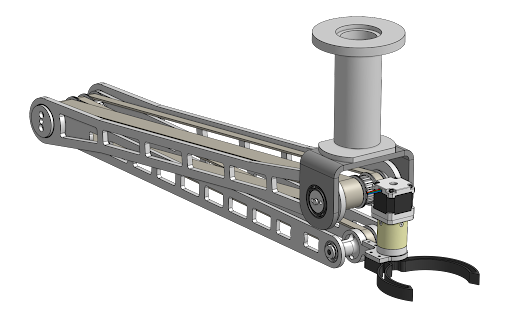

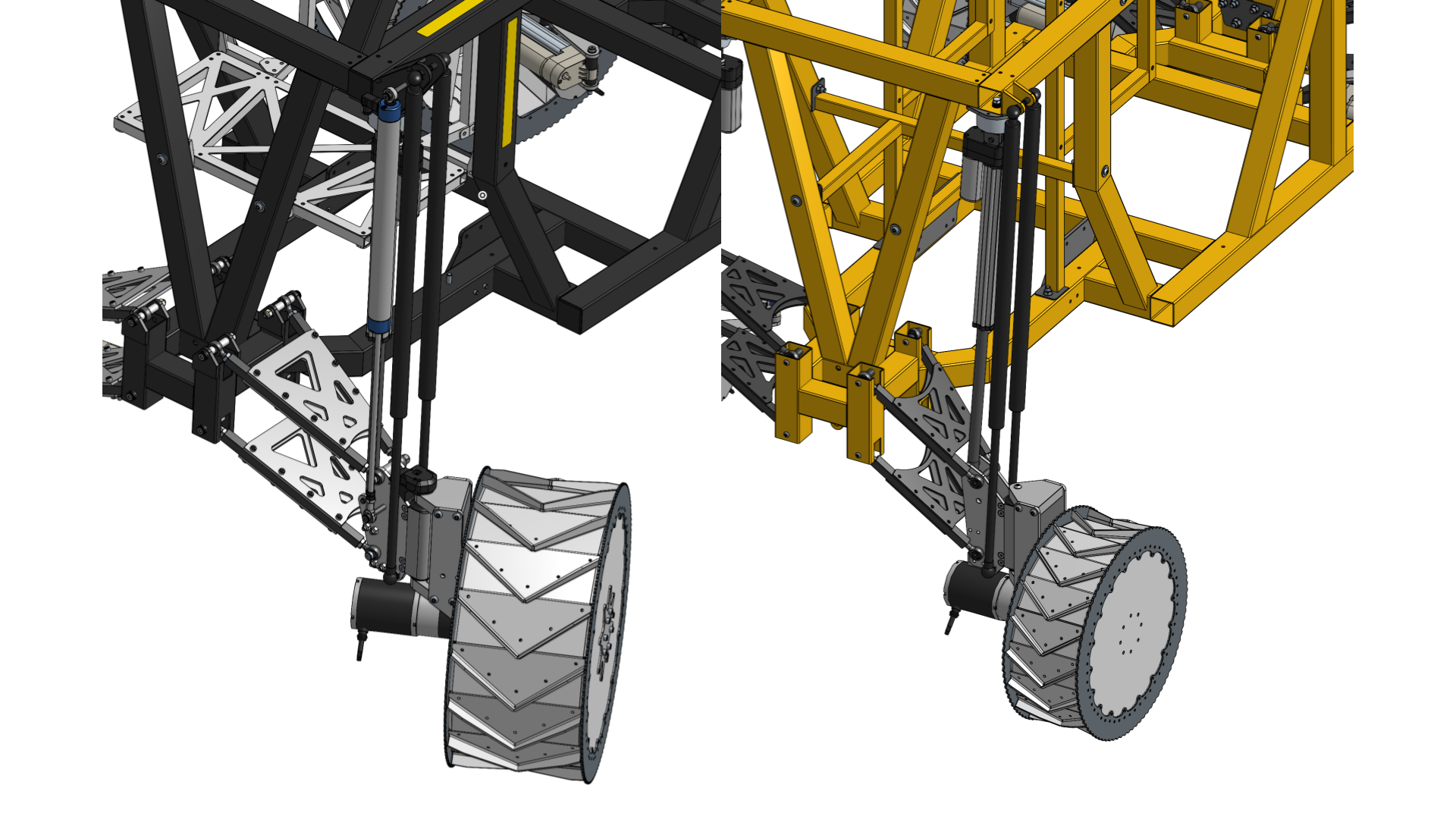

Suspension Overhaul:

- Adapted existing kinematic layout geometry to new wheel envelope

- Redesigned A-arm mounts and most suspension components

- Modified frame to support extended wheelbase and larger wheels

- Implemented 30°/30° steering angle

Level 3 (left) vs Level 2 (right) suspension assembly

Integration Under Fire

Fast design meant some components were modeled just days before fabrication. This required:

- Constant communication with excavation/electrical teams

- On-the-fly modifications when reality didn't match CAD

- Balancing "perfect" vs "good enough" to meet deadlines

The payoff: 85% excavation rate improvement enabled by a chassis that could handle the increased loads, and 100% drivetrain reliability.

Final Results & Reflection

The rover secured 3rd place overall at NASA's Break the Ice Lunar Challenge, validating our scrappy approach against teams with significant industry backing. More importantly, this project transformed my engineering practice. The PSTDL gave me the freedom to fail fast and get hands on. Working alongside a team that trusted an undergrad to work as an engineer, designing and redesigning critical systems, taught me that good engineering isn't about perfection; it's about making the right compromises under pressure.

Team photo after successful competition

NASA Video

I cannot thank the PSTDL enough for the opportunity to be on such an amazing team.